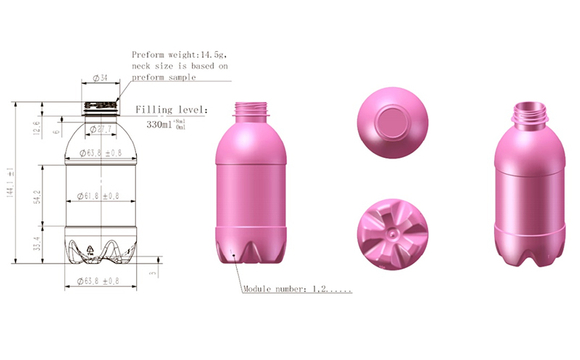

Custom Bottle Design

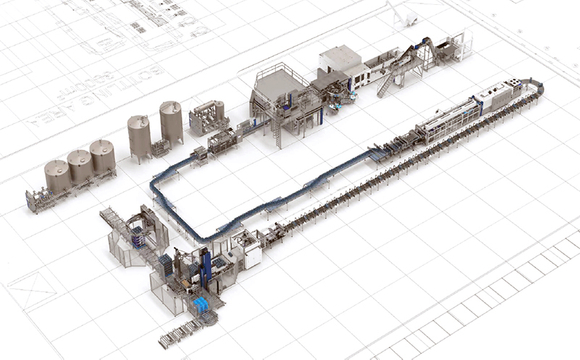

WEIS provide the one-stop service from A to Z of turkey project solution in order to save customer time and cost avoid trouble in future project carrying out process. Custom bottle design is the 1st step in the turkey project. According to reference bottle samples and modification requirement from clients side, WEIS re-design bottle drawing, provide PET preform weight, make trail mold, get trial bottle sample, so that client can imagine the final real bottle view. After whole project confirmed and signed, the cost will be deducted from the turkey project value. Every year, the custom bottle design is over than 50 times.